Article

citation information:

Cieślar,

K., Nowakowski, J. Knefel, T. Dynamic numerical stress analysis of a crankshaft of

internal combustion engine. Scientific

Journal of Silesian University of Technology. Series Transport. 2025, 127, 23-37. ISSN: 0209-3324. DOI: https://doi.org/10.20858/sjsutst.2025.127.2

Kacper CIEŚLAR[1], Jacek NOWAKOWSKI[2], Tomasz KNEFEL[3]

DYNAMIC NUMERICAL

STRESS ANALYSIS OF A CRANKSHAFT OF INTERNAL COMBUSTION ENGINE

Summary. Dynamic numerical

stress analysis of a crankshaft subjected to load at selected operational

points of a diesel engine is presented in this paper. The calculations and the

analyses were carried out for six values of engine rotational speed and for two

temperature values of engine structural elements. At each operating point of

the engine, the piston-crank system was loaded with maximal gas pressure force,

and additionally, inertia forces resulting from rotational speed of the

crankshaft were taken into consideration. The analysis was carried out to

obtain the distribution of the stress and to indicate critical areas where

concentration of the stress may occur. In addition, the analysis was extended

to other operational factors, such as the determination of the natural

frequency of vibrations and effects of maximal torque on torsion of the

crankshaft.

Keywords: crankshaft, FEM, ANSYS, numerical calculations, thermal calculations

1. INTRODUCTION

In

an internal combustion engine equipped with a piston-crank system, exhaust gas

pressure is converted into torque. Its direction, turn, and value of the load

are changing in time and can result in material fatigue. Phenomenon of material

fatigue is caused by cyclic changes in the stress; however, the course of this

phenomenon also depends on other factors, e.g., temperature

-

combustion

gas pressure force,

-

inertia

force,

-

friction

force.

The

pressure of gases in the cylinder changes, and is the highest at the beginning

of the expansion stroke.

The

inertia forces are present during the movement of masses in the piston-crank

mechanism, and their values are a function of the mass of its components and

accelerations of its individual elements.

All

masses of the crank mechanism can be grouped into:

-

the

masses concentrated in the center of the piston pin, and performing

reciprocating movement (piston with its pin and rings),

-

the

masses concentrated in the center of the crankpin of the crankshaft, performing

rotational motion (crankshaft),

-

the

masses of the conrod – performing complex moves (composed of reciprocating and

rotational moves). For this reason, masses of the conrod are replaced by a

system of two equivalent masses, and it is assumed that part of this mass is

concentrated in the center of the piston pin and performs reciprocating

movement, and the other part of the mass is concentrated in the center of the

crankshaft’s journal and performs rotational movement.

The

friction forces are considerably restricted by lubrication, and compared to the

others, such forces reach small values, and due to this, in the majority of the

analyses, these are neglected.

The

crankshaft must be robust enough to carry the load acting on it and ensure

reliable operation of the internal combustion engine. High-volume production of

components as the crankshaft requires its proper design and preliminary testing

before putting it into production. In such cases, numerical analyses allow

verification of the crankshaft in terms of strength as well as optimization of

its shape and dimensions, reducing manufacturing costs.

The

Finite Element Method is a type of numerical analysis allowing finding, in an

approximate and discrete way, a function describing the behavior of a given system (boundary problem) under certain

given conditions by dividing a complex problem (e.g., with complex shape) into

a finite number of elements (having a simpler geometry).

In

the study

In

the study [11] optimization of the crankshaft was performed in range of its

geometry and shape without effects on the structure of the cylinder block and

cylinder head of the engine. The optimization was carried out mainly on the

shape of counterweights, removing parts of material with slight changes in the

strength properties simultaneously allowing for a reduction in the weight of

the complete crankshaft by 4.37%.

The

numerical analysis [10] may also comprise strength analysis of the crankshaft

at several points of engine operation, and not only in extreme cases such as

the TDC and position for maximum tangential force. In this study, there were

also undertaken calculations for three different materials.

The

Finite Element Method also allows for predicting areas most susceptible to

damage. In the paper [1], the service life of the crankshaft of a six-cylinder

diesel engine of a truck was determined, modeling the

growth of fatigue cracks with the use of linear fracture mechanics. The results

of the calculations were confirmed by experimental tests.

The

results of the numerical calculations using the Finite Element Method are

implemented for analysis of various types of damage and to identify areas on

the crankshaft structure that are weak in terms of strength and which require

improvements. The following methodology was adopted in the article [8]: a model of the crankshaft is generated

in a computer system destined for advanced computer-aided design (CAD). The

Finite Element Analysis is next performed in the ANSYS system under static and

dynamic conditions to obtain changes in the stress at key areas. Data of the

engine, boundary conditions, and mechanical properties are taken into account

as the input data.

The

FEM [12] allows examination of an

effect of inclusions, e.g., manganese and sulfur, in

the structure of the steel of the crankshaft on its strength properties. In the

article, the structural model was precisely replicated from the real geometry

of a damaged crankshaft and divided into octahedral, tetrahedral elements

having the number of nodes equal to ten (ten-node tetrahedral). Analysis of

convergence of the mesh showed that values of reduced stress are convergent

when the size of the FEM element is 2 mm, and appears in the same areas as the

real damages. This will allow for predicting areas of probable damage.

Simulation

methods are also useful in the course of measuring of the crankshafts. In the

study [9], it was proposed a

measurement system developed on the basis of numerical calculations to support

the crankshaft with the use of flexible supports. This allowed elimination of

effects of reaction forces of the supports and thus elimination of deformations

of the crankshaft regardless of any possible deviations, e.g., concentricity of

the main journals. Values of the forces were calculated using the Finite Element

Method, based on these values, it was found that reaction forces change not

only on the supports but also in cases when the angular position of the

crankshaft is changing.

The

Finite Element Method enables thermal simulations as well. In the article [7],

there is presented analysis of displacements of the crankshaft's axis under

influence of temperature in a low-speed marine engine. Information about the

thermal displacements of the axis of the power transmission system is important

when determining the linearity of the crankshaft and its bearings. Thermal

displacements of the crankshaft calculated by numerical analysis have shown

a higher value than recommended by the manufacturer. The difference is not

large (less than 20%), but it may be a source of additional bending torque

and shearing force acting between the crankshaft and the cylinder block. The

calculations have shown that the manufacturer's assumption about parallel

displacement of the axis of the crankshaft is incorrect.

The

modeling may include analyses of low temperatures

[3]. In the article is presented a method to determine the shrinkages of

the main elements of the V6 engine (the crankshaft mainly) with a small

displacement for the cold phase at extremely low temperatures. The phenomenon

of thermal shrinkage generates mechanical wear of surfaces of rotating elements

in components of the engine. Based on calculations using the ANSYS program, in

the study it was proposed a suitable mathematical model enabling selection of

the fits at extremely low temperatures.

In

many cases, the phenomenon of vibrations can have decisive meaning in the

proper functioning of the crankshaft [5]. The vibrations may cause the

combustion engine to malfunction. The occurrence of phenomena of resonance may

cause an increase in amplitude of the vibrations, which may result in damage to

the crankshaft and related components. Regardless of the dynamics of the system

in which the engine operates, the greatest threat is caused by torsional

vibrations of the crankshaft.

In the

article is described the influence of selection of computational mesh on

results obtained during simulation of the crankshaft of a diesel engine.

Presented here, the methodology may be useful for performing calculations for a

new crankshaft. In the case of determination of mode of vibrations only, a

smaller mesh with a larger element can be used. It should be emphasized,

however, that the selection of elements of the mesh and its density must be

consistent with the geometric model. The smaller mesh elements, the more

accurate results, which has an effect on significant prolongation of the

calculations.

The

article [2] describes a study on the causes of premature failure of a

high-pressure diesel engine crankshaft. It was noted that all crankshafts

failed in the same part, namely the first crankpin. Dynamic analysis and finite

element modeling were conducted to determine the

stress state in the crankpin. The results of the finite element method showed

that the crankpin throw was the most susceptible to cracking. The Soderburg diagram for the analyzed

crankshaft indicated that the operational point, which signifies the values of

mean and alternating stresses in the critical crankpin throw area, was within

the safe zone. The results suggest that the failure was induced by overload,

with no signs of fatigue. It was recommended to reevaluate the design and production,

as well as optimize the crankpin throw rolling process. This recommendation was

adopted by the manufacturer, and since then, no further cases of failure have

been reported. The article concludes that the analysis of the crankshaft

failure helped eliminate fatigue as a cause and highlighted the need for

redesigning and reconstructing the project and production processes.

The

research [15] focused on analyzing various aspects

related to the failure of a diesel engine crankshaft. Initially, a visual

inspection of the damage was conducted, revealing signs of material fatigue at

the fracture site. Subsequently, material tests confirmed that the mechanical

properties of the crankshaft material were within the norm. However,

microcracks were found in the area of crack initiation, suggesting that the

damage could have been caused by material fatigue. Numerical analysis indicated

that the maximum stresses in the crack initiation area were relatively low

compared to the material's ultimate strength, suggesting that the fracture

could have been due to operational conditions. Moreover, modal analysis showed

that the second mode of vibration might be responsible for the damage to the

crankshaft in the crack initiation area. Based on these findings, several

corrective and improvement actions were proposed, such as increasing the fillet

radius on the connecting rods, further material testing, and implementing a

rolling process for the connecting rod fillets to prevent similar failures in

the future.

The

authors [4] proposed a methodology encompassing several key steps in the design

of crankshafts. Firstly, it utilizes advanced computer-aided design (CAD)

tools, such as CATIA, to precisely develop the crankshaft model. Next,

numerical analyses are conducted using ANSYS software, including stress

assessment, deformation analysis, and fatigue life prediction. In the

subsequent step, researchers perform design optimization aimed at reducing the

weight of the crankshaft with minimal impact on its strength and functionality.

The entire process is based on advanced computer engineering techniques,

allowing for precise analysis and optimization.

In

their conclusions, the authors emphasize the significance of integrating ANSYS

software in the design and development process of crankshafts. They indicate

that this tool enables higher efficiency, reliability, and performance in

internal combustion engines. Ultimately, this review suggests that the synergy

between ANSYS software and crankshaft development can lead to further

innovations in the automotive industry, paving the way for more sustainable and

efficient internal combustion engines in the future.

2. OBJECT OF

THE ANALYSES AND SCOPE OF THE NUMERICAL CALCULATIONS

The

crankshaft of an internal combustion engine plays an important role in

converting reciprocating motion of elements of the crank mechanism into

rotational motion. The complex state of the stress variable and significant

values of the load to which the crankshaft is subjected mean that this

component must be designed very carefully. Appropriate stiffness of this

component must be assured with possibly small dimensions. These dimensions

determine the size of the engine and therefore the possibilities of its

installation.

The

objective of this study was to determine the stress present in the crankshaft

operating at various rotational speeds. Efforts were taken to approach this

issue as broadly as possible. Therefore, in addition to the stress, the

displacements were determined, both for the load mentioned above and maximum

torsional torque; also, modal analysis of the crankshaft was performed.

The

crankshaft of a diesel engine to light road traction was analyzed.

The engine data is shown in Table 1.

Tab.

1

Technical

data of the internal combustion engine

|

Type of the engine |

Compression

ignition engine, CR system, turbo supercharger |

|

Layout/number of cylinders |

in – line engine /

4 |

|

Displacement |

1248 ccm |

|

Maximal power output |

55.2 kW at 4000 rpm |

|

Maximal torque |

190 Nm at 1500 rpm |

The

calculations and the analyses were performed for six values of engine

rotational speed: 1000, 2000, 3000, 3500, 4000, 4500 rpm. They cover the entire

operational range of engine speeds and enable assessment of an impact of the

load on the stress and the displacements. The calculations were performed for

two load cases. In the first one, it was assumed that for each of the

considered rotational speeds, the same force acts on the crankshaft,

constituting 75% of the maximum force loading the crank. There were

considered two temperature values of the engine's structural elements: 323 and

353K. The second case consists of the assumption that the crankshaft is loaded

on the cylinder axis by force resulting from the sum of the forces: gaseous and

inertia. The gaseous force was determined based on measurement of the pressure

in the combustion chamber. The maximum value of this force was taken for each

from the rotational speeds. In turn, the value of the inertia force was

determined for each rotational speed. Fig. 1 shows the summary value of the

force acting in the axis of the cylinder for the second loading case.

Fig. 1. Change of value of

the force acting on

the crankshaft for the second load case of the crankshaft

The

crankshaft was also subjected to the modal analysis. In combustion engines,

there are occurring periodically variable forces caused by changing pressure in

the cylinder and inertia forces. They result in torsional, flexural, and

longitudinal vibrations of the crankshaft and elements connected to the

crankshaft. In extreme cases, these vibrations can lead to resonance, and the

stress generated by the vibrations can cause damage to components of the engine

or their premature wear. Normally, analysis of torsional vibrations of the

crankshaft is carried out because such vibrations create the greatest risk in

case of the resonance. In order to estimate the natural vibrations of the

crankshaft, computational methods are used, which are based on the reduction of

the real vibrating system to a simpler equivalent system and use of one or more

analytical methods. However, the analysis of the torsional vibrations only does

not provide a complete picture of the issue, especially in the case of

multi-cranked crankshafts, where resonance may occur between the main journals.

To obtain a more comprehensive analysis, the Finite Element Method is used.

The

reduction of the real system, in the case of analytical methods, consists in

dividing the system into smaller parts and, next, determining their inertia and

torsional flexibility of the sections connecting adjacent parts. In order to

simplify the analysis, the division is often limited to individual crank

mechanisms, flywheels and auxiliary drives, main drives, vehicle drives, or

power take-off drives.

Simpler

analysis methods include methods for reducing the real crankshaft to

a single-mass, dual-mass, or three-mass equivalent system. To perform

analysis of the natural vibrations of the tested crankshaft after usage of the

reduction, the method of successive approximations, known as the Holzer method,

is also used. In this article, only the Finite Element Method was used.

Use

of the Finite Element Method to the issue of determination of natural frequency

of the crankshaft enables determination of all modes of vibrations, not only

torsional modes. The frequency analysis was performed using the ANSYS package.

The

following physical model supported in the main bearings and being able to

rotate freely was analyzed.

Supporting

conditions of the crankshaft in the main bearings were modeled,

allowing the main journals to move in direction of longitudinal axis.

After

carrying out the analyses, the properties of the steel from which the

crankshaft was made were determined: yield strength = 350 MPa, and ultimate

tensile strength = 420 MPa. Additionally, the following parameters were adopted

for calculations: density 7870 kg/m3, Young’s modulus = 210000 MPa,

Poisson's ratio = 0.3.

3.

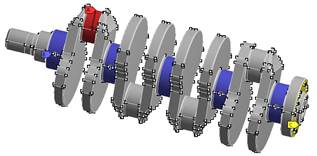

CONSTRUCTION OF THE NUMERICAL MODEL

The

solid model of the crankshaft was created in the NX program. The model prepared

in this way and written in the format appropriate for the NX program (.stp) was exported to the ANSYS WORKBENCH software. The

calculations were prepared in the Transient Structural module used for dynamic

analysis of the system under the influence of time-varying loads. The mesh was

created using the Uniform function, which does not correct the shape of the

mesh because of dimensions and curvature of geometry. The mesh consists of

elements with 1 mm size; number of the nodes for a complete crankshaft amounts

to 6845909, and the number of the elements amounts to 1608812. Selection of an

appropriate size of the FEM element involves a compromise between accuracy

of the solution, available computational resources, and numerical stability.

Typically, smaller FEM elements lead to more accurate results because they

better model complicated shapes and gradients of areas. The size of the

elements was taken based on the previous experience of the authors [14],

striving to obtain accurate results of calculations because preliminary earlier

calculations, based on elements of various sizes, have indicated the need for

local thickening of the mesh up to 1 mm. In most cases the element size is a

compromise between the accuracy and time of the calculations. The mesh

generated on the model of the crankshaft is shown in Fig. 2.

Fig. 2.

Meshed model of the crankshaft

The boundary conditions, i.e., the force loading the

crankshaft and its support, were assumed in the following way: the crankshaft

was fixed using the cylindrical constraints in the crankshaft main bearing

journals, leaving the possibility of rotation of the crankshaft, while the

loading force was imposed on the surface of the crankpin in the angular range

from 0° to 120°. The boundary conditions as applied in the analyzed model are

presented in Fig. 3.

Fig. 3.

Boundary conditions applied to the crankshaft

4.

ANALYSIS OF RESULTS OF THE NUMERICAL CALCULATIONS

In the first step, numerical analyses were performed

applying load on the crankshaft with equal force, constituting approximately

75% of the maximal load on the crank. As expected, the highest values of the

stress and the deformations occur in the crankpin. Examples of calculation

results are shown in Fig. 4 (stress) and in Fig. 5 (deformations). The

deformations of the crankshaft fragments remain in the linear range, and for

better illustration, they are presented on scale of 1500:1.

Fig. 4.

Stress in the loaded crank for 1000 rpm

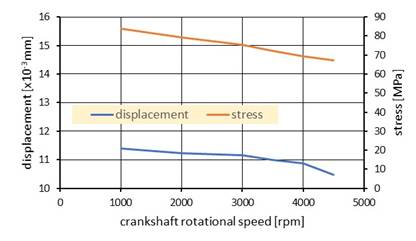

In the Fig. 6 are shown calculated values of

the displacements and the stress for temperature of 323K. The calculated values

of the displacements of the crankshaft operating at this temperature vary from

11.4 µm at 1000 rpm, to 10.47 µm at 4500 rpm, and therefore, by just over 8%.

The stress values for the temperature of 323K

change within a bigger range, i.e., from 83.96 MPa to 67.236 MPa, and hence, by

almost 20%.

Fig. 5.

Total deformations for 1000 rpm (in scale 1500:1)

Fig. 6.

Displacements (blue color line) and stress (brown color line) of the crankpin

calculated for the temperature 323K

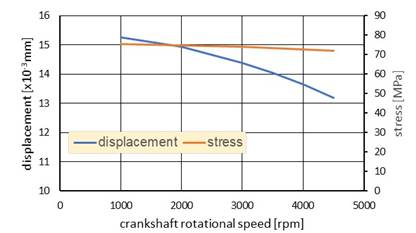

A similar character of the courses can be

observed for temperature of 353K (Fig. 7). However, in this case the

displacement values are higher - they change from 33.9 µm to 31 µm, i.e., by

8.5%. The stress calculated for the temperature of 353K shows a slightly higher

values and changes from 84.1 MPa to 68.1 MPa, i.e. by 19%.

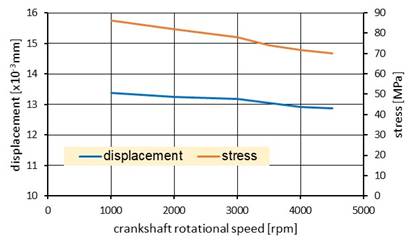

In the successive step, calculations were made for

loading of the crankshaft with a force acting in the axis of the cylinder. The

results of the calculations for the loaded crankpin are presented in Fig. 8÷10.

And thus, together with increasing rotational speed, for

temperature of 293K, the displacement values decreased from 15.3 µm to 13.2 µm,

i.e., by 13.6%. However, the stress decreased only by 4.5% (from 75.4 MPa to

71.9 MPa, Fig. 8).

Together with increasing rotational speed, for the

temperature of 323K, the displacements value decreased slightly, from 13.4 µm

to 12.9 µm, i.e., by 3.7%. There was a significant change in the stress values

- from 86.4 MPa to 69.9 MPa, i.e., by 19% (Fig. 11).

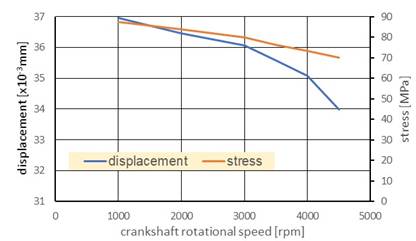

In turn, for the temperature of 353K, increasing the

rotational speed results in decreasing the displacements value from 36.9 µm to

33.9 µm (by 8%), and the stress value to decrease from 87.3 MPa to 70.2 MPa,

i.e., by 19, 7% (Fig. 10).

In the course of the calculations, the values of the

stress and displacements at the free end of the crankshaft had taken negligible

values and were not subjected to the analyses.

Fig. 7.

Displacements (blue color line) and stress (brown color line) of the crankpin

calculated for the temperature 353K

Fig. 8.

Displacements (blue color line) and stress (brown color line) of the crankpin

calculated for the temperature 293K

Fig. 9.

Displacements (blue color line) and stress (brown color line) of the crankpin

calculated for the temperature 323K

Fig. 10.

Displacements (blue color line) and stress (brown color line) of the crankpin

calculated for the temperature 353K

The results of the modal analysis are

presented in Table 2. The modes of vibrations were classified as a bending,

torsional and longitudinal ones, based on the dominant direction of the

displacement along the axis (X), or in transverse directions (Y, Z), or also in

the direction of the angle of rotation of the crankshaft. In the case of the

crankshaft, it is possible to talk only about the dominance of a specific form

of vibrations over the others, due to the complex, spatial nature of the

vibrations, especially in the case of the modes with a higher frequency.

Tab.

2

Natural

frequencies and modes of vibration

|

Mode |

Frequency [Hz] |

Modes of the

vibrations |

|

1 |

3918.4 |

Bending |

|

2 |

3918.6 |

Bending |

|

3 |

3922.8 |

Bending |

|

4 |

3922.9 |

Bending |

|

5 |

3933.3 |

Bending |

|

6 |

3934.3 |

Bending |

|

7 |

3946.8 |

Bending |

|

8 |

3947 |

Bending |

|

9 |

3950.6 |

Bending |

|

10 |

4261.6 |

Torsional |

|

11 |

4264.7 |

Torsional |

|

12 |

4266.2 |

Torsional |

|

13 |

4277.8 |

Torsional |

|

14 |

4278.3 |

Torsional |

|

15 |

4292.1 |

Torsional |

|

16 |

4292.4 |

Torsional |

|

17 |

4297.5 |

Torsional |

|

18 |

6006.5 |

Longitudinal |

|

19 |

6059.3 |

Longitudinal |

|

20 |

6087.9 |

Longitudinal |

|

21 |

6115.9 |

Longitudinal |

|

22 |

6442 |

Bending |

|

23 |

6442.3 |

Bending |

|

24 |

6443.4 |

Bending |

|

25 |

6444.9 |

Torsional |

|

26 |

6445.2 |

Torsional |

|

27 |

6447.9 |

Torsional |

|

28 |

6448.2 |

Torsional |

|

29 |

6449.8 |

Torsional |

|

30 |

6728.4 |

Longitudinal |

As can be noticed, all natural frequencies of

the existing types of vibrations lie outside the range of useful rotational

speeds of the analyzed crankshaft.

5.

CONCLUSIONS

Performed analyses constitute an attempt at a

complex method of proceeding, which enables determination of the stress and

displacements of the crankshaft of a modern, high-speed diesel engine. The

analyses have allowed determination of a role of calculated values in assessing

critical stress-strain of the material value and to identify areas that should

be designed with a particular care. The analyses have confirmed that

selection of the material is very important because it determines usage of

components having dimensions specified during the designing stage. After

carrying out calculations, it should be stated that analyzed crankshaft of the

engine was designed so that excessive stress values will not occur. Stiffness,

in spite of small overlapping of the crankshaft main bearing journal and the

crankpin, was ensured by using the appropriate thickness of walls. However,

special attention should be paid to transitions from the crankpin to the crank

arm. During the calculations, increased stress values were found in these

areas. In the opinion of the authors, after performing analysis of many cases,

increased stress values that appear in these areas result from peculiarities of

the FEM method. Hence, the need for completing calculations performed so far

with analyses that would take into account their special character.

The

analysis of the shaft calculation results shows that both displacements and

stresses decrease with increasing rotational speed. These changes are caused by

the unloading effect of the centrifugal force associated with the crankshaft,

which reduces the total value of the loading force.

The presented

stress values are reduced stresses and do not exceed the permissible values

specified for the crankshaft material.

Because displacement values decrease with

increasing crankshaft speed, the smallest journal-to-bearing clearance values

can be expected at low rotational speeds and high crankshaft material

temperatures. Please be advised that bearing housings may also experience

deformation as a result of elevated temperatures. The authors performed

additional analyzes of the crank bearing clearances and found that there was no

risk of bearing sticking in the considered range of rotational speeds and

temperatures.

From analysis of results of the calculations

of the crankshaft loaded with constant force is seen that temperature has a

small effect on values of the stress, but has important effect on values of the

displacements, which practically increase almost three times when temperature

changes from 323K to 353K. At a given operating temperature of the crankshaft,

a similar range of the changes in both the displacements and the stress takes

place (Fig. 11).

Fig. 11.

Percentage change of the displacements and stress calculated for various values

of temperature of the crankpin loaded with constant force acting on axis of

cylinder

Analyzing the results of the crankshaft calculations

loaded with force acting on axis of the cylinder, it can be noticed that the

stress increases with increasing temperature, while the most significant is

increase in the temperature in the range from 293 to 323K. Changes in the

displacements are ambiguous: after a slight decrease in temperature range of

293K÷323K, there occurs a significant increase in the range of 323K÷353K. At a

given operating temperature of the crankshaft, the changes both in the displacements

and the stress are different (Fig. 12), resulting from change in the crankshaft

load by a force acting on the cylinder axis (Fig. 1).

Fig. 12.

Percentage change of the displacements and stress calculated for various values

of temperature of crankpin loaded with a force acting on the cylinder axis

Using of the Finite Element Method enables a

comprehensive approach to the issue of natural vibrations of the crankshaft

because it allows for the determination of all possible modes of vibrations,

not only these of a torsional nature, as this takes place in the case of

analytical methods. Unfortunately, such an approach involves significant labor

required to prepare a computational model properly. However, owing to it,

it is possible to obtain a more complete picture of the crankshaft’s behavior

during vibrations, what is particularly important for more complex modes of

vibrations with higher frequencies. The crankshaft, due to its high stiffness

and method of its supporting, exhibits a dangerous phenomenon of resonance at

the level of 3918 Hz, which corresponds to rotational speed of 235080 rpm,

impossible to be achieved in operating conditions of the internal combustion

engine.

Numerical analyses using the finite element

method have proven useful for designing and analyzing structural components,

such as crankshafts. These calculations provide valuable information about the

behavior of crankshafts under various operating conditions and temperatures.

This information helps to optimize the shape and dimensions of crankshafts,

improving efficiency and reducing manufacturing costs.

These numerical calculations have proven

useful in designing and analyzing structural elements, such as crankshafts.

Despite the accuracy of the FEM method, each engine is tested intensively in

the prototyping phase for mechanical and thermal durability. However, one

should always consider changes in the material resulting from the machining

process in relation to the idealized computer model. This issue particularly

concerns elements exposed to friction and thermal loads. These processes enable

the final evaluation of the product.

References

1.

Aliakbari K., M. Imanparast, R.M. Nejad.

2019. „Microstructure and fatigue

fracture mechanism for a heavy-duty truck diesel engine crankshaft”. Scientia

Iranica 26(6): 3313-24.

2.

Farrahi G.H., S.M. H-Gangaraj, S. Abolhassani, F. Hemmati, M. Sakhaei. 2011. “Failure Analysis of a Four Cylinder Diesel

Engine Crankshaft Made From Nodular Cast Iron”. The Journal of Engine

Research 22: 21-28.

3.

Haba S.A., G. Oancea.

2015. “Studies on thermal contraction of crankshaft bearings under extreme low

temperatures”. Journal of Thermal Science 24(5): 496-501. DOI: https://doi.org/10.19206/CE-2019-443.

4.

Kumar S., Y. Mishra,

R. Sahu. 2024. “A review paper on design and development of crankshaft analysis

and modeling using ANSYS software”. International Journal of Progressive

Research in Engineering Management and Science 4(1): 106-9.

5.

Magryta P., K. Pietrykowski, K. Skiba. 2017. “FEM

simulation research of natural frequency vibration of crankshaft from internal

combustion engine”. ITM Web of Conferences 15: 07004.

6.

Mroziński S., R. Skocki. 2015. „Wpływ

temperatury na wyniki obliczeń trwałości zmęczeniowej”. [In

Polish: “Mechanicznej Developments In Mechanical

Engineering”]. Czasopismo naukowo-techniczne

– Scientific-Technical Journal 6(3): 43-55.

7.

Murawski L. 2016. “Thermal

displacement of crankshaft axis of slow-speed marine engine”. Brodogradnja 67(4): 17-29.

8.

Navathale T., N. Kharche, S. Shekokar,

D.P. Kharat. 2021. “A Review on Finite Element Analysis of the Crankshaft of Internal

Combustion Engine”. International Research Journal of Engineering and

Technology 6(Special Issue 01): 352-355. ISSN: 2456-236X.

9.

Nozdrzykowski K., Z. Grządziel, R. Grzejda,

M. Warzecha, M. Stępień. 2022. „An Analysis of Reaction Forces in Crankshaft

Support Systems”. Lubricants 10(7): 151.

10.

Sandya K., M. Keerthi,

K. Srinivas. 2016. “Modeling and stress analysis of crankshaft using Fem

Package Ansys”. International Research Journal of Engineering and Technology

03(01): 687-693.

11.

Shahane V.C., R.S. Pawar.

2017. “Optimization of the crankshaft using finite element analysis approach”. Automotive

and Engine Technology 2(1-4): 1-23.

12.

Tiana

L., N. Dinga, L. Liua, N. Xua, W. Guoa,

X. Wua, H. Xua, C.M. Wu. 2023. “Fracture failure of the

multi-throw crankshaft in a sport utility vehicle”. Engineering Failure

Analysis 145: 107036. DOI: 10.1016/j.engfailanal.2023.107036.

13.

Urbaś A., A. Harlecki,

J. Nowakowski, A. Byrski. 2013. „Analysis of dynamics of the piston-crank system of a selected internal

combustion engine with the use of the MSC.ADAMS and ANSYS software interface”. Combustion

Engines 154(3): 1076-1083. ISSN: 0138-0346.

14.

Wawrzyczek J., T. Knefel. 2019. “Stress analysis of the cylinder block of a small

compression ignition engine”. Combustion Engines 179(4): 259-263. ISSN: 0138-0346.

15.

Witek L., F. Stachowicz, A. Załęski.

2017. „Failure investigation of the

crankshaft of diesel engine”. Proceedings of the 2nd International

Conference on Structural Integrity, ICSI. 4-7 September 2017.

Funchal, Madeira, Portugal. Structural Integrity Procedia. 2017.

Received 05.12.2024; accepted in revised form 20.01.2025

![]()

Scientific Journal of Silesian

University of Technology. Series Transport is licensed under a Creative

Commons Attribution 4.0 International License